Construction Job Management: Complete Guide With Best Practices

Every construction site is a puzzle of people, tasks, and deadlines. Crews clock in at different times, subcontractors overlap, materials arrive late, and weather can disrupt even the best-laid plans. Amid this complexity, success does not come from high-level planning alone. It depends on how well each day’s work is managed on the ground — something modern job management software for contractors increasingly supports.

This is the essence of construction job management. It is the practice of coordinating the daily execution of tasks so that projects stay on time, within budget, and safe. While project management sets the overall strategy, job management focuses on the reality of the jobsite. It is about making sure crews know what to do, hours are tracked, and issues are resolved before they grow into costly delays. For subcontractors, tools like project management software for subcontractors help align field work with overall project plans.

When job management is done well, it brings structure to the natural chaos of construction. When it is neglected, the result is wasted labor, missed deadlines, and unhappy clients. Many contractors now rely on construction job software to prevent this — especially when combined with strong construction documentation management practices that keep drawings, files, and records organized across teams.

In this guide, we will explain:

- What construction job management really means

- Why it matters for contractors, supervisors, and crews

- The biggest challenges companies face

- How modern crew-focused solutions are transforming the way jobs get done

Table of Contents

Table of Contents

Why Construction Job Management Matters

At first glance, “job management” might sound like a buzzword. In practice, it touches every aspect of a project and often makes the difference between a profitable job and one that drains resources. Here’s why it matters:

1. Productivity and Efficiency

- Prevents wasted hours caused by poor sequencing or late deliveries.

- Keeps crews in the right place at the right time.

- Reduces idle time and maximizes output.

2. Cost Control

- Tracks labor hours accurately — the biggest construction expense.

- Provides real-time visibility into planned vs. actual costs.

- Protects profit margins by catching overruns early.

3. Accountability and Transparency

- Assigns clear responsibilities for each task.

- Creates traceable records of schedules, work completed, and pending tasks.

- Reduces finger-pointing and builds trust between teams and clients.

4. Safety and Compliance

- Integrates safety checklists, hazard reports, and daily briefings into workflows.

- Ensures risks are flagged quickly to prevent accidents.

- Improves morale and reduces fines by maintaining compliance.

5. Reputation and Client Satisfaction

- Helps deliver projects on time and within budget.

- Minimizes surprises, delays, and disputes.

- Strengthens credibility and encourages repeat business.

Bottom line: Job management is where plans become reality — and why many teams turn to contractor job management software to stay organized

Traditional vs. Digital Job Management: Why Software Wins

For decades, construction companies have relied on manual methods to organize jobs. Paper timesheets, phone calls, wall calendars, and endless Excel spreadsheets were the standard. These tools worked well enough when projects were small and teams were limited, but today they often create more problems than they solve.

Traditional Job Management: The Old Way

- Paper and Whiteboards: Easy to start with, but hard to scale. Paper gets lost, and whiteboards only help the people standing in front of them.

- Spreadsheets: Flexible, but prone to errors and version chaos. A single wrong formula or outdated file can throw off a week’s worth of planning.

- Phone Calls and Messaging Apps: Fast, but impossible to track. Important instructions disappear in chat history, and accountability is lost.

The result is a system that relies heavily on memory, personal follow-ups, and trust. For small crews, it may hold together. For larger projects with multiple subcontractors, it often leads to confusion, delays, and hidden costs.

Digital Job Management: The Modern Way

Digital tools replace scattered methods with a centralized system where scheduling, time tracking, reporting, and communication all connect. The key advantages are:

- Real-Time Updates: Everyone sees the same information, whether on-site or in the office.

- Data Accuracy: No more duplicate entries or miscalculations in spreadsheets.

- Accountability: Tasks are assigned, tracked, and documented, so nothing slips through the cracks.

- Mobility: Crews can check schedules, log hours, and report issues directly from their phones.

Why the Shift Matters

The shift to digital job management is not just about technology — it’s about making construction more predictable and less stressful. When communication flows smoothly and data is accurate, supervisors spend less time chasing updates and more time focusing on building. For teams aiming to integrate field and office processes, exploring modern ERP systems for the construction industry can further streamline operations across departments.

Still running jobs with spreadsheets and whiteboards? See how digital job management tools like Remato Crew Management cut down on errors and keep everyone aligned in real time.

5 Key Elements of Construction Job Management (That Prevent Costly Delays)

Good job management is not about adding more paperwork or extra layers of control. It is about breaking the complexity of construction into clear, manageable parts. When contractors understand these elements, they can identify where problems usually start and where improvements will have the biggest impact — especially when paired with reliable job progress tracking software.

1. Crew Scheduling

Without clear schedules, jobsites quickly descend into confusion. Crews may arrive before materials are delivered, or two subcontractors might get assigned to the same space at the same time. Effective scheduling means:

- Assigning the right people to the right tasks.

- Matching skill sets with job requirements.

- Avoiding downtime by sequencing work correctly.

2. Time Tracking and Attendance

Labor is often the single largest cost in construction. Accurate time tracking is critical for payroll, job costing, and forecasting. Poor attendance records lead to budget surprises and disputes. Digital systems make it easier for crews to log hours directly from site, reducing errors and delays.

3. Task Assignment and Monitoring

Tasks that are not clearly assigned tend to fall through the cracks. Job management should define:

- Who is responsible for each activity.

- When it should be completed.

- How progress will be tracked. This accountability not only drives productivity but also builds trust between supervisors and crews.

4. Daily Reporting

Reports are not just for compliance. They capture the pulse of the project:

- what was done today,

- what problems were faced,

- and what comes next.

Good daily reporting ensures that small issues (like a missing delivery or equipment breakdown) are flagged before they become major delays.

5. Communication and Coordination

Miscommunication is one of the biggest sources of wasted time in construction. Instructions passed verbally or via text messages are easy to forget or misinterpret. Centralized job management keeps communication structured, documented, and visible to all stakeholders.

Takeaway: These five elements, scheduling, time tracking, task assignment, reporting, and communication, form the backbone of effective job management. If even one of them is weak, the whole project feels the impact.

Common Challenges in Construction Job Management

Even the most experienced contractors and site managers face obstacles when managing daily jobs. For this reason, job management for contractors becomes essential to keeping workflows predictable and preventing avoidable disruptions. Understanding these challenges is the first step toward solving them.

1. Delays and Idle Time

According to a McKinsey Global Institute study, large construction projects typically take 20% longer to finish than scheduled and run up to 80% over budget. One major cause is poor coordination of crews, equipment, and materials. If a delivery is late or tasks are not sequenced properly, workers stand idle, and productivity suffers.

2. Inaccurate Time and Cost Tracking

Many contractors still rely on paper timesheets or spreadsheets. The Construction Management Association of America (CMAA) highlights that inconsistent time records are a leading cause of disputes between contractors and clients. Without reliable data, it is nearly impossible to forecast costs accurately or protect profit margins.

3. Miscommunication Across Teams

The Occupational Safety and Health Administration (OSHA) notes that miscommunication on construction sites is not only costly but also dangerous. When instructions are unclear or undocumented, mistakes pile up, safety protocols are skipped, and accountability disappears.

4. Safety Risks and Compliance Issues

Slips, trips, falls, and equipment accidents remain the most common causes of workplace injuries. OSHA reports that 1 in 5 worker deaths in the United States occurs in construction (OSHA Fatal Four) with poor site management being a major contributing factor. Without proper reporting and crew coordination, hazards are often overlooked.

5. Lack of Accountability

When responsibilities are vague, accountability fades. This leads to finger-pointing when deadlines are missed or quality issues arise. Inconsistent job management creates a culture of blame rather than collaboration, which drags down morale and efficiency.

In summary: construction job management is not just an administrative burden. Done poorly, it creates delays, budget overruns, disputes, and safety risks. Done well, it prevents them before they ever surface.

Best Practices in Construction Job Management

Effective job management is not about doing more, but about doing the essentials consistently and clearly. Below are proven practices that contractors and site managers can adopt to improve efficiency, reduce risk, and deliver better outcomes — a foundation that strengthens overall contractor job management across every project.

1. Plan at Both the Project and Job Level

High-level project schedules are important, but they must translate into daily and weekly job-level tasks. Break down long timelines into short, clear crew assignments. This helps avoid confusion on site and keeps progress measurable.

2. Use Real-Time Communication

Miscommunication is one of the leading causes of delays and accidents. Research from OSHA shows that clear, consistent communication reduces incidents significantly. Standardize how instructions are shared: whether through a central platform, shift briefings, or structured daily logs.

3. Track Time Accurately and Transparently

According to CMAA, inaccurate labor records remain a top source of disputes. Make time tracking simple for crews and transparent for supervisors. Whether through mobile check-ins or digital timesheets, reliable data is the foundation of accurate job costing.

4. Prioritize Safety Within Job Management

Job management is not just about productivity; it is also about crew safety. Incorporate safety checklists, toolbox talks, and hazard reporting into daily workflows. The OSHA “Fatal Four” accidents (falls, struck-by, electrocution, caught-in/between) can often be prevented through consistent monitoring.

5. Establish Clear Accountability

Every task should have a single responsible person. Shared responsibility often means no responsibility. Job management systems should clarify who is assigned, what the deadline is, and how progress is reported. This transparency avoids finger-pointing later.

6. Monitor Progress With Daily Reporting

Daily job reports capture the reality of the site — what was done, what issues occurred, and what comes next. They keep owners, supervisors, and clients aligned. As the McKinsey Global Institute highlights, companies that adopt consistent reporting practices deliver projects 30% faster with fewer cost overruns.

7. Embrace Digital Tools for Scalability

Paper and spreadsheets may work for a small team, but they do not scale. Digital job management platforms make

- scheduling,

- time tracking,

- communication,

- and reporting all part of one system.

This reduces

- errors,

- increases visibility, and

- gives managers more time to focus on building rather than chasing information.

Key takeaway: Best practices in job management are not abstract theories. They are daily habits: planning in detail, communicating clearly, tracking accurately, prioritizing safety, and ensuring accountability. When supported by modern digital tools, these practices turn complex projects into predictable, well-managed jobs.

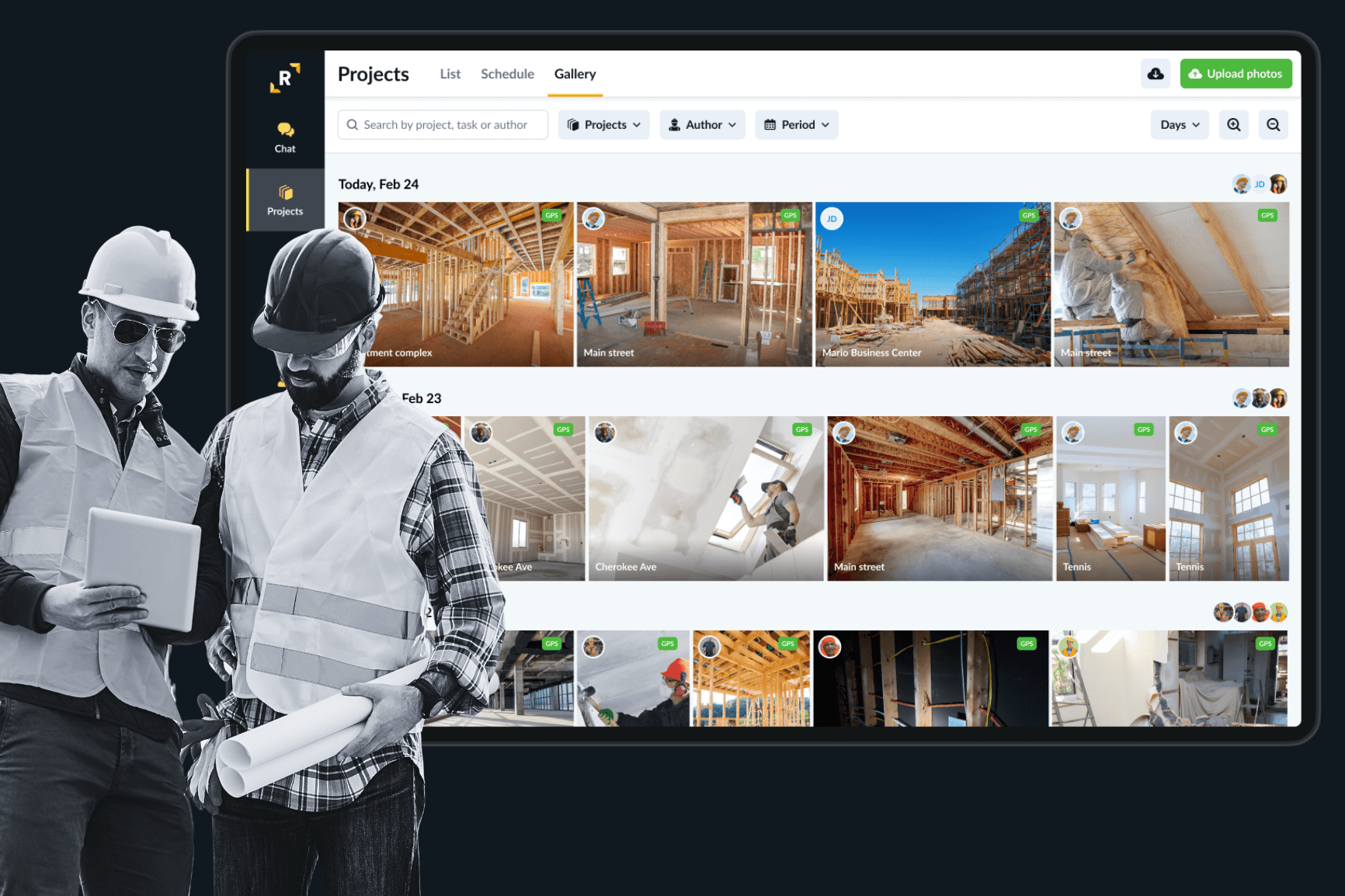

The Role of Job Photos in Construction Job Management

Job photos are more than just snapshots of progress — they are an essential tool for accountability, communication, and risk management on the jobsite. Modern job management systems, especially any construction job app used in the field, increasingly integrate photo capture because visual documentation fills the gaps that text and spreadsheets can’t.

Why Job Photos Matter

- Progress Tracking

- Provide a clear, visual record of what was completed each day.

- Help supervisors and clients see real progress without needing constant site visits.

- Accountability

- Show who did the work and when.

- Reduce disputes by creating objective evidence of completed tasks or site conditions.

- Safety and Compliance

- Document that safety protocols (like PPE use, scaffolding setup, or hazard signage) are followed.

- Provide proof for compliance with OSHA or local regulations.

- Issue Resolution

- Capture problems (e.g., damaged deliveries, site hazards, weather delays) instantly.

- Share photos with suppliers, subcontractors, or insurance providers for faster resolution.

- Client Communication

- Keep owners in the loop with visual updates.

- Build trust by making progress transparent and easy to verify.

Best Practices for Job Photos

- Standardize what should be photographed (daily progress, safety checks, deliveries).

- Organize photos by project, date, and task for easy retrieval.

- Use mobile-friendly job management tools so crews can upload photos directly from the site.

- Combine photos with daily reports for a complete project record.

Takeaway: Job photos transform construction job management from words and numbers into a visual story of the project. They protect contractors, keep crews accountable, and give clients confidence that the job is progressing as promised.

Frequently Asked Questions About Construction Job Management

What is construction job management?

Construction job management is the process of organizing and coordinating daily work on a jobsite. It includes scheduling crews, tracking time, assigning tasks, reporting progress, and ensuring safety. Unlike project management, which focuses on the overall plan, job management deals with the day-to-day execution.

How is job management different from project management?

Project management looks at the big picture such as budgets, contracts, design phases, and overall strategy. Job management focuses on execution on site, making sure today’s tasks get done by the right people at the right time. Both are essential, but job management is where plans turn into real work.

Why do contractors need job management software?

Paper and spreadsheets lead to errors, delays, and missing information. Modern job management software for contractors keeps data accurate, real-time, and accessible from anywhere.

Who benefits the most from construction job management?

Contractors gain better control of budgets and deadlines. Supervisors spend less time chasing updates and more time focusing on quality and safety. Crews know exactly what is expected and can report issues easily. Clients see projects delivered on time and with fewer surprises.

What are the biggest problems caused by poor job management?

Poor job management often leads to delays, wasted labor, and cost overruns due to inaccurate time tracking. It also results in miscommunication that causes rework, and safety risks when instructions are unclear or hazards go unreported.

Does job management improve safety?

Yes. Many jobsite accidents occur because safety instructions were unclear or hazards were not reported quickly. According to OSHA, most workplace incidents are preventable with proper communication and monitoring. Job management systems make safety part of daily workflows.

How does job management affect project costs?

Labor is the largest cost in most construction projects. Better job management ensures time is tracked accurately, crews are scheduled efficiently, and issues are flagged early. This prevents budget overruns and improves profit margins.

Is job management only for large projects?

No. Even small crews benefit from structured job management. In fact, smaller contractors often see the biggest gains because they have fewer people to absorb mistakes. Clear scheduling, accurate hours, and organized reporting pay off at every scale.

What are the first steps to improving job management?

The first steps are to start with clear scheduling and task assignments, make time tracking simple for crews, standardize daily reporting to catch issues early, and then gradually adopt digital tools that fit the team’s needs.

Conclusion

Construction job management is the bridge between planning and execution. It is where schedules, budgets, and strategies become real work on the ground. When handled well, it brings order to the chaos of the jobsite. Crews are scheduled correctly, hours are tracked accurately, and safety is taken seriously. When handled poorly, the result is delays, disputes, and unnecessary costs.

By focusing on best practices such as clear scheduling, reliable time tracking, structured communication, and consistent reporting, contractors can transform the way their jobs are run. The shift from paper and spreadsheets to digital tools — including a modern construction job app — makes this process faster, more transparent, and far less stressful.

The reality is simple: strong job management does not just improve productivity. It protects profits, reduces risks, and builds a reputation for reliability that wins repeat business.

If you are ready to simplify scheduling, time tracking, and daily reporting for your crews, it may be time to consider a modern solution. Remato Crew Management is designed to make job management straightforward for contractors, supervisors, and teams in the field. It keeps everyone on the same page and turns complex projects into predictable, well-managed jobs.