Stop Losing Tools: Practical Asset Tracking Solutions

This guide covers practical asset tracking methods for small and medium businesses in construction, cleaning, and public services. Learn how to track tools using QR codes, stainless steel tags, and user-friendly software to cut costs, improve accountability, and boost efficiency.

Table of Contents

Why Asset Tracking Matters for Small Businesses

Tools, equipment, and other physical assets are the lifeblood of many small and medium-sized businesses – especially in hands-on industries like construction, maintenance, and field services.

But without a reliable way to track those assets, businesses face avoidable losses every day — in both time and money. Tools go missing, equipment sits unused because no one knows where it is, and teams waste valuable hours searching instead of working. Over time, this leads to higher replacement costs, missed deadlines, and frustrated workers.

That’s why inventory and asset management isn’t just about organization — it’s a direct lever for improving productivity, reducing theft, and protecting your bottom line.

The Cost of Poor Asset Tracking

The impact of poor asset tracking is serious:

- Construction companies face $300 million to $1 billion in losses annually due to missing tools and equipment.

- Up to 30% of all tool purchases in the sector are replacements for lost, stolen, or broken items

- Field workers spend up to 90 minutes per day searching for tools.

That’s money lost and productivity down the drain.

What Is Asset Tracking?

Asset tracking, also known as tool tracking or equipment asset management, is the process of monitoring:

- What assets you own

- Where they are

- Who is using them

- Their condition and service history

Whether you’re managing an enterprise-level equipment register or just want to track a few company laptops, the goal is the same: avoid chaos, reduce losses, and make your inventory visible and manageable.

Use QR Codes and Barcodes for Cost-Effective Asset Tracking

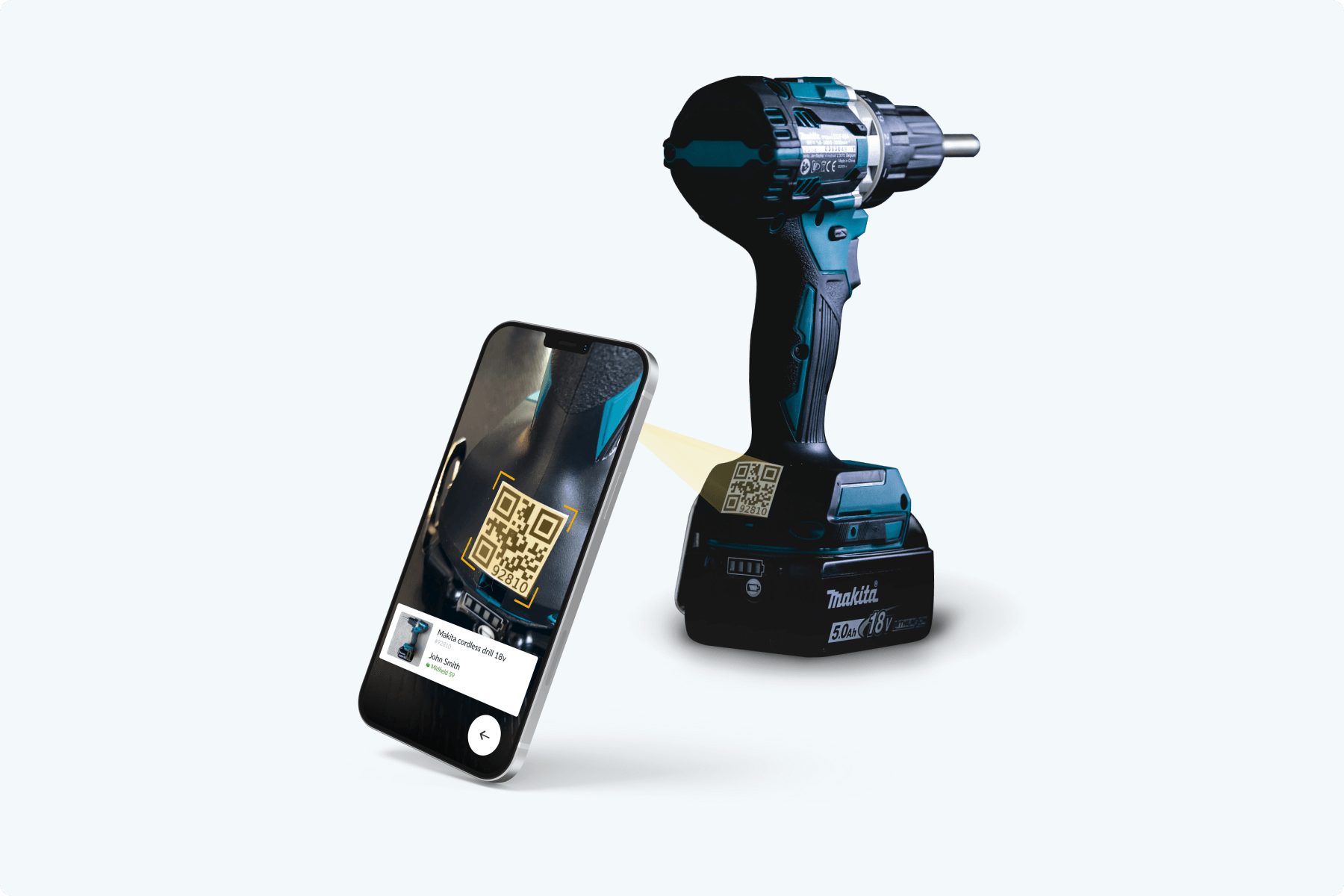

One of the easiest and most cost-effective ways to start tracking assets is by using QR code and barcode stickers. These are labels that you attach to each tool or piece of equipment, printed with a unique QR code (or traditional barcode) that corresponds to that item’s profile in your system. When someone needs the item, they can simply scan the code with a smartphone to log a check-out or view information about the tool. If you don’t already have custom codes, you can easily generate QR codes online to get started.

How it works

- Create a digital record for each tool in an asset management app.

- Print or buy a QR or barcode sticker containing a unique ID.

- Affix the sticker to the tool or equipment.

- Workers can scan the code using a smartphone to:

- View tool info

- Check it in/out

- Log damage or maintenance

Why It Works

Using QR/barcode stickers for asset tracking is popular because:

- Low cost and easy deployment: Printing QR code stickers is inexpensive, and you can label everything from power drills to laptops in minutes. There’s no need for special hardware beyond a standard printer and smartphones.

- Quick information access: A scan instantly brings up the tool’s info. No more flipping through paper logs or spreadsheets – your digital software asset register updates in real time.

- Improved accountability: If every tool has a code and every transaction (check-out, handoff, return) is logged by scanning, it creates a clear chain of custody. Employees know tools are being monitored, which fosters a culture of accountability.

- Fewer errors: Scanning a code is more reliable than manual data entry. It prevents typos or mix-ups, ensuring that the right item is recorded every time.

Adopting QR code labels essentially integrates tool tracking into your everyday workflow. For a contractor or service company, this turns managing tools from a tedious chore into a quick scan-and-go routine – making inventory management for construction projects (and others) much simpler and more accurate.

Tip: Use weatherproof, heavy-duty stickers so labels don’t peel off in tough conditions. Thanks to built-in error correction, a QR code can often still be read even if part of it gets scratched.

Durable Equipment Tags: When to Use Stainless Steel QR Labels

For assets that face extremely harsh conditions, stainless steel QR code tags are a go-to solution. These are metal tags (usually stainless steel or anodized aluminum) etched or printed with a QR code or barcode. You can attach them to equipment with screws, rivets, or strong adhesive. Stainless steel tags cost more than stickers, but they offer unmatched durability.

When to use metal tags

If you have tools constantly exposed to weather, abrasion, heat, or chemicals, a standard sticker might not last. For example, think of equipment stored outdoors year-round, or tools that get pressure-washed regularly. Metal QR code tags offer superior resistance to weather and chemical exposure. They won’t easily tear, fade, or corrode, even in tough environments. This makes them ideal for long-term asset monitoring in construction yards, factories, or any demanding setting.

Benefits of stainless steel QR tags

- Extreme durability: These tags withstand rain, sun, high temperatures, and rough handling – conditions that would destroy a paper label. They’re often used to manage fixed assets where longevity is key.

- Long-term value: While the upfront cost is higher, you likely won’t have to replace a metal tag for many years (if ever). For high-value tools or equipment with long service life, a one-time metal tag ensures the asset’s ID remains intact.

- Secure attachment: Fastening tags with screws or rivets makes them hard to remove. That deters casual theft or tampering. (By contrast, someone might peel off a sticker, but removing a bolted metal plate requires effort.)

- More info if needed: Metal tags can accommodate extra info (e.g. a serial number or company name) alongside the QR code, since you can use both the code and engraved text.

For most small tools, heavy-duty stickers do the job. But for certain cases – say a tool’s label keeps getting destroyed – upgrading to a stainless steel tag is a smart move. Many asset tracking systems (from full-fledged construction company asset management software to simpler apps for small businesses) support both sticker labels and metal tags, since the QR code itself works the same way. The key is to ensure the code on a metal tag is high-contrast and well-printed, so it scans as easily as a sticker.

Advanced Asset Tracking: RFID, Bluetooth, and GPS Explained

QR codes and barcodes are simple and accessible, but more advanced tracking technologies exist as well – notably RFID, Bluetooth, and GPS-based systems. These can take asset tracking to the next level, though they involve greater investment and setup.

- RFID asset tracking: RFID tags can be scanned in bulk without direct line-of-sight. This makes rapid inventory counts possible (e.g. waving an RFID reader near a toolbox could detect all tagged tools inside). It’s powerful for large inventories (some companies use RFID IT asset tracking to manage data center hardware), but RFID requires special readers and infrastructure, so it may be hard to justify for smaller operations.

- Bluetooth beacons: These small tags broadcast a Bluetooth signal to a mobile app. It’s useful to see if a tool is nearby on a jobsite. However, Bluetooth range is limited (usually up to a few dozen meters) and the tags need batteries.

- GPS trackers: For large equipment or vehicles, GPS devices can transmit real-time location data from anywhere. This is great for theft recovery and fleet management, but GPS trackers require power (battery or wiring) and typically a data plan for connectivity.

These high-tech methods often feature in enterprise-level asset management. In fact, some of the best EAM software suites for big companies integrate options like RFID or IoT sensors. However, for most small and mid-sized businesses, such systems are overkill – simpler solutions like QR code tags give you the most bang for your buck. We mention these options to acknowledge they exist for specialized needs, but we won’t delve deeper into them here.

Final Thoughts: Why Every Business Needs an Asset Tracking System

By implementing even a basic tool tracking system, your business gains:

- Lower losses and replacement costs

- Improved crew productivity

- Clearer maintenance scheduling

- Greater accountability

Whether you run a field service team, construction company, or public works crew, tracking your tools doesn’t have to be expensive or complex.

Ready to Stop Losing Your Company Assets?

Remato’s asset tracking software makes it easy for field teams to manage tools, assign equipment, and track maintenance – all from one mobile-friendly platform.