The Rise of Modular and Timber Construction in Europe: Sustainable Solutions for 2025 and Beyond

Modular and Timber Construction is gaining traction across Europe as a response to climate pressure, housing shortages, and a push for efficiency. This discussion begins with pioneering projects like Stockholm Wood City, then surveys public investment trends, before shifting to specific innovations in Poland, Estonia, and Ireland. Throughout, we draw on peer-reviewed research to anchor claims.

Table of Contents

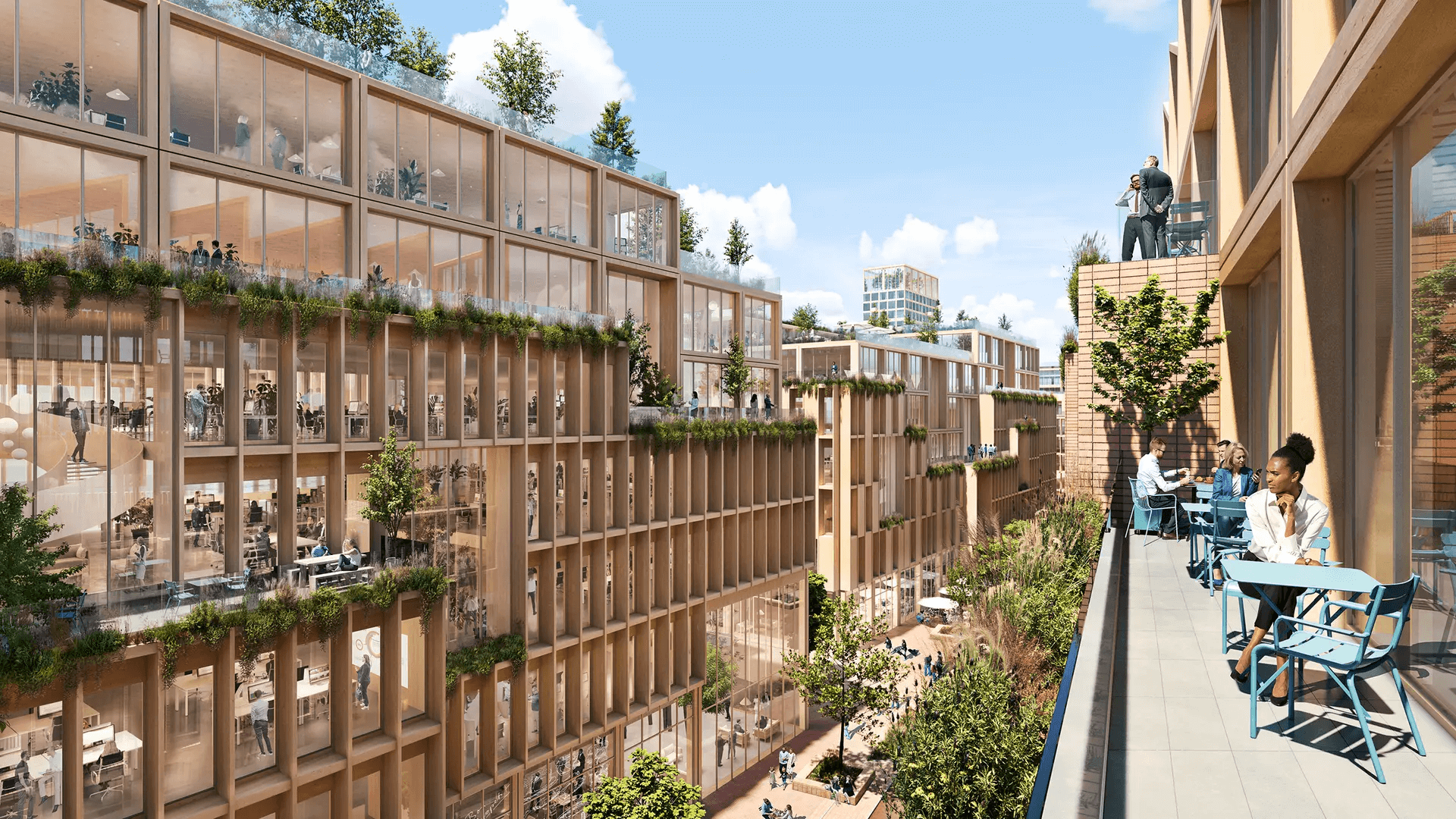

A Landmark Case: Stockholm Wood City

Stockholm is leading with Stockholm Wood City, the world’s largest city intentionally built largely from engineered wood using modular and mass-timber methods. It aims to deliver 2,000 homes by 2027, alongside schools, offices, and public spaces (source). The speed of timber construction up to 1,000 m² per week versus 500 m² with concrete is remarkable. Furthermore, carbon emissions are slashed by 40 %, and the project aligns with Sweden’s target for climate neutrality by 2030. Aalto University figures suggest that if 80 % of new European buildings used wood for structure and finishes, up to 55 million metric tons of CO₂ could be sequestered annually by 2040, almost half of what Europe’s cement industry emits yearly.

Modular and Timber Construction, in action at this scale, shows that environmental gains can be combined with human wellbeing benefits. Wood interiors reduce stress, improve concentration, and create a more pleasant environment for both inhabitants and builders.

Broader European Trends and Policy Drivers

Across the continent, Modular and Timber Construction is being embraced for public buildings, housing, and infrastructure. For instance, London’s “Paradise SE11” is the UK’s lowest-carbon mass-timber office development it removes some 1,800 tonnes of CO₂, about the footprint of constructing 24 traditional homes. Similarly, mass-timber products such as CLT and glulam are being used in the Zurich airport terminal and the Paris 2024 Olympic aquatic centre. Despite concerns around fire safety, biodiversity (from forestry), and insurance, regulations are adapting and many countries now encourage timber use, especially in France, the UK, and the Netherlands.

Researched Benefits of Modular and Timber Construction

Going into scientific literature that reveals quantifiable advantages of Modular and Timber Construction:

- A 2025 review (“Advancing global mass timber construction”) explains how mass timber ensures sustainability, structural capacity, and tall-building feasibility, especially when standardised modules are prefabricated off-site ScienceDirect.

- The life-cycle study “Modular multi-storey construction with cross-laminated timber” (2023) highlights environmental implications and benefits of volumetric CLT elements, confirming substantial GHG savings over traditional methods Taylor & Francis Online.

- “Environmental consequences of shifting to timber” (2024) adds nuance by analysing environmental impact categories, reinforcing that timber construction lowers climate footprint when properly managed ScienceDirect.

- The i-RESIST project emphasises design for adaptability, reuse, and deconstruction, showing that prefabricated CLT modules drastically reduce embodied carbon and construction waste while enabling long lifespans and rapid disassembly for reuse EU Science Hub.

- A pilot from UCL (2024–2025) tested mass secondary timber, reused timber from demolition, transformed into CLST and glulamST modules, designed for adaptation and reuse across locations. It demonstrated feasibility and scalability potential Proceedings.com.

- A bibliometric study (2024) tracked 409 articles on prefabricated and modular timber construction, showing growth in research around circular economy and digital technologies though gaps remain in understanding practical implementation ResearchGate.

These studies collectively show how Modular and Timber Construction offers sustainability, efficiency, and circularity, provided regulatory, supply-chain, and design challenges are addressed.

Space Efficiency in High-Rise Timber Projects

High-rise modular and timber buildings are efficient:

A 2024 study of 56 European cases found average space efficiency at 82 %, with core area only about 11 % of gross floor area. Design variables like core layout, materials, and forms had limited impact on efficiency implying timber high-rises can be space-effective MDPI.

Construction software in modular and timber construction

These projects depend on precision timing and coordination between factories, transport, and on-site assembly. Unlike traditional builds where delays can sometimes be absorbed, modular methods require crews, cranes, and prefabricated elements to arrive and align at exact moments any disruption can stall the entire process. Digital platforms help manage this complexity by tracking workforce availability, monitoring equipment use, scheduling deliveries, and keeping communication transparent.

Crew tracking is usually more critical than tools tracking.

Here’s why:

- Tight assembly schedules: modules often arrive by truck in a fixed sequence, and the site crew must be ready at the exact time. If the crew isn’t where they should be, delays cascade quickly.

- Specialised labor: timber installation requires trained workers (e.g., CLT installers, crane operators). Tracking ensures the right specialists are on site when needed.

- High daily costs: cranes, transport, and prefabrication plants run on expensive schedules. A missing crew can waste tens of thousands in a day.

Meanwhile, tool tracking is useful but secondary:

- Large timber projects don’t use a huge variety of small tools on-site (most precision cutting is done in the factory).

- What matters more are heavy machines (cranes, lifts), usually rented or managed separately.

So in modular and timber projects, crew tracking delivers higher value, especially when coordinating between factory, transport, and site assembly.

Specific National Highlights: Poland, Estonia, Ireland

Poland

- Modular DA Houses: Designed by Dom Architektów, these homes showcase modern wooden residential designs in Poland. [source]

- Spectis Report: A comprehensive analysis of Poland’s modular construction market, highlighting growth trends and key players. [source]

Estonia

- Loodusmaja (“Nature House”): Located in Tallinn, this is Estonia’s largest wooden building, exemplifying sustainable construction practices. [source]

- BAU 2025 Exhibition: Estonian companies showcased innovations in modular timber construction, digitalisation, and serial renovation at the BAU 2025 event in Munich. [source]

Ireland

- Naturally Grown Timber Pilot Project: A collaboration between South Dublin County Council, Coillte DAC, MediteSmartply, and University of Galway, aiming to demonstrate the potential of homegrown timber in constructing social houses. [source]

- “Wood First” Initiative: The Irish government is promoting timber as the primary construction material for public buildings, including homes, schools, and libraries, to address the housing crisis and support sustainability. [source]

Outlook: Scaling Up Modular and Timber Construction in Europe

Modular and Timber Construction is important in sustainable urban development.

- Europe’s construction industry is expected to grow at ~2.1 % annually in 2025–2026, supported by public spending on energy-efficient renovation, affordable housing, and resilient infrastructure. Modular, timber-based approaches fit well into that agenda.

- Large-scale projects like Stockholm Wood City show what’s possible. Meanwhile, national pilots in Poland, Estonia, and Ireland suggest that decentralised and localised innovation can coalesce into a broader movement.

- Scientific evidence on carbon benefits, waste reduction, space efficiency, and circular strategies lays a strong foundation for policy, investment, and further design innovation.

- Nevertheless, ongoing research is needed to resolve fire-safety, biodiversity, insurance, and material-sourcing challenges; and cross-sector collaboration will be key.

Furthermore, as technologies like digital modelling and prefab systems mature, Modular and Timber Construction may increasingly become the standard rather than the exception.

Conclusion

Modular and Timber Construction is deep in European building practices. Environmental performance, cost advantages, construction speed, and occupant wellbeing converge to make it a compelling alternative. As seen in Stockholm Wood City, Paradise SE11, and pilot schemes across Poland, Estonia, and Ireland, real-world gains are becoming tangible. Scientific studies confirm broad benefits, from lifecycle emissions to reuse, while also spotlighting areas that still require attention. With thoughtful policy and continued innovation, Modular and Timber Construction can guide Europe toward a more resilient, low-carbon, and humane built environment.