Construction Site Safety: EU Directives and Site-Specific Training

Construction is one of the most hazardous industries in the EU. Construction site safety is a system designed to prevent accidents, ensure legal compliance, and protect every worker so they return home safely. Two critical pillars underpin this system: the EU Framework Directive 89/391/EEC and the PPE Use Directive 89/656/EEC, complemented in practice by site-specific training.

Table of Contents

EU Framework Directive 89/391/EEC

Council Directive of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work. This directive is about risk prevention and safe systems of work before PPE even comes into play.

It’s the “master directive” so called umbrella law that sets the general principles for protecting workers’ health and safety in all sectors. It doesn’t list every specific hazard or piece of PPE; instead, it creates a system where:

- Employers must identify hazards (risk assessment).

- Employers must eliminate or reduce risks at the source before relying on PPE.

- Workers must be informed and trained about risks and protective measures.

- Preventive culture is prioritised over reactive accident handling.

Key Principles:

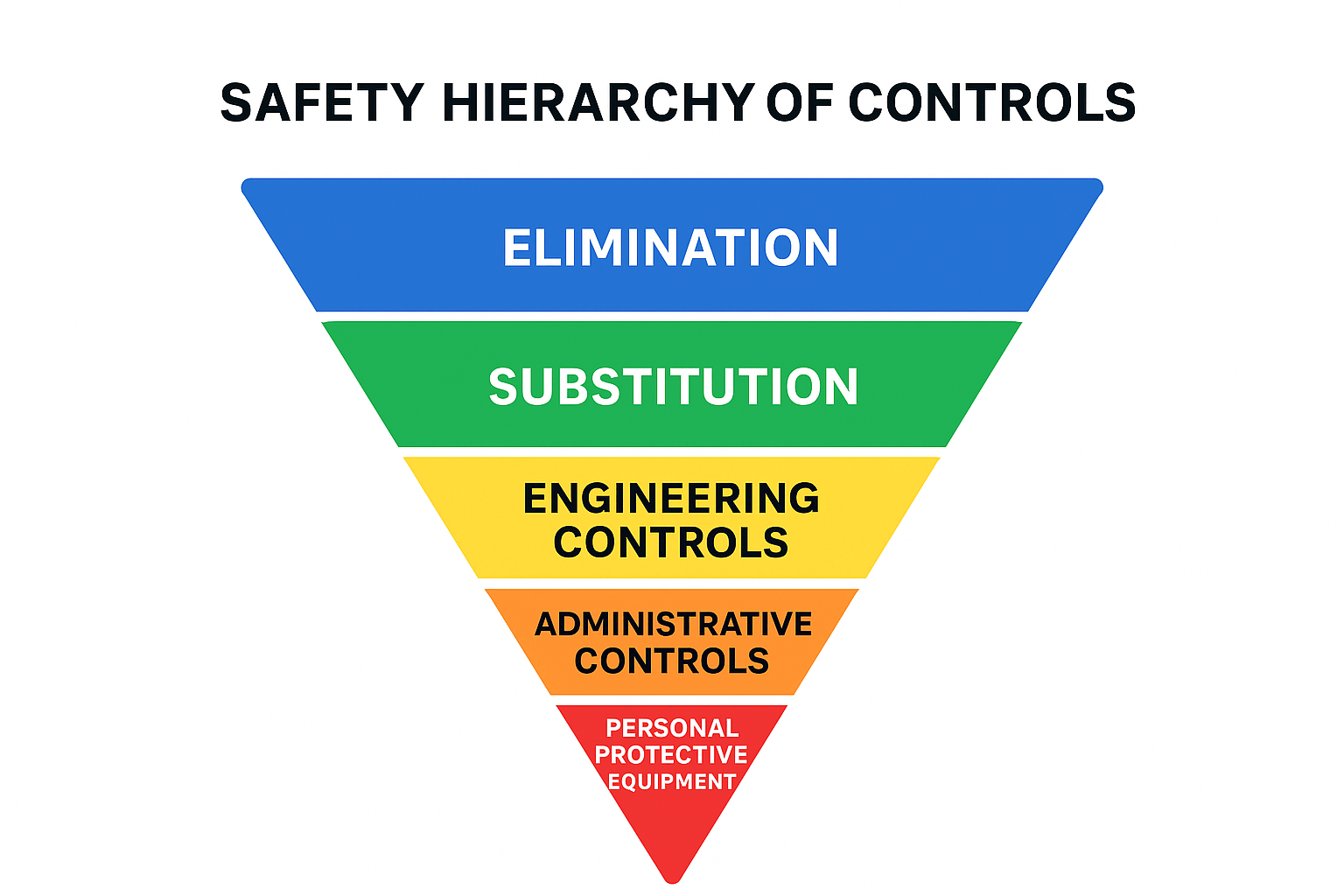

- Hierarchy of controls:

- Avoid the risk entirely (e.g., use a safer method).

- Tackle risks at source (e.g., guard machinery).

- Adapt work to the individual (e.g., ergonomics).

- Use collective protection before personal protection.

- Provide PPE only as a last resort.

- Worker involvement: Workers have the right to be consulted on safety issues and to refuse dangerous work.

- Employer responsibility: Safety can’t be delegated entirely to workers; it’s the employer’s legal duty to provide a safe workplace.

It’s the legal basis that obliges a site manager to first try to prevent a falling brick (netting, guardrails) before simply telling workers “wear a helmet.”

Example applications:

- Risk assessment before starting a project

- Before building a multi-story scaffold, the site manager must analyze collapse risks, load-bearing capacity, weather impact, and fall protection needs.

- Outcome: Guardrails and toe boards are installed before the first worker climbs up.

- Avoiding risks rather than just protecting against them

- Instead of having workers cut concrete with hand-held grinders (dust + noise), the contractor uses a stationary saw with integrated water suppression and an extraction system.

- Outcome: Less silica dust exposure, less PPE dependency.

- Worker involvement

- During a site safety briefing, workers point out that a delivery zone is too close to the walkway.

- Outcome: Delivery zone is moved and barriers installed, reducing struck-by hazards.

PPE Use Directive 89/656/EEC

Council Directive of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace. This kicks in when risks cannot be eliminated and PPE is the last line of defense. PPE means any equipment or clothing designed to protect a worker from one or more health and safety risks, worn or held by the worker, and provided free of charge by the employer.

While the Framework Directive says “protect workers,” this one gets specific about how PPE should be selected, provided, and used.

Main Rules:

- Employer obligations:

- Provide PPE free of charge.

- Ensure PPE is appropriate for the risk and complies with CE marking under EU PPE Regulation (EU) 2016/425.

- Maintain, clean, repair, or replace PPE as needed.

- Provide training on correct use, limits, and storage.

- Risk-based selection: PPE must match the exact hazard (e.g., high-vis clothing for traffic, cut-resistant gloves for steelwork).

- Exclusive use: PPE is generally for personal use only, no “community” hard hats unless properly sanitised.

- Comfort and fit: PPE must fit the user and not create additional risks (e.g., loose gloves around rotating machinery).

This is why you don’t just get “any boots” , you get boots that meet EN ISO 20345 S3 if there’s a puncture risk, or a helmet that meets EN 397 if there’s a falling object risk. It also explains why a foreman can’t just tell you “buy your own” , it’s the employer’s legal duty to supply it.

Examples in construction:

- Hard hats → protect the head from falling objects.

- High-visibility vests → make workers visible to machinery operators and drivers.

- Safety boots → prevent foot injuries from crushing or sharp objects.

- Gloves → protect from cuts, abrasions, heat, or chemicals.

- Goggles or face shields → protect eyes from dust, debris, sparks.

- Respirators or masks → protect lungs from dust, fumes, asbestos fibers.

- Harnesses → protect against falls from height.

Reflective Vests (High-Visibility Clothing)

Purpose: Makes workers visible to vehicle operators, machinery, and other workers — especially in low light, near traffic, or in dusty conditions.

Design: Must meet EN ISO 20471 standards, which specify brightness, retroreflective properties, and coverage.

Colors: Fluorescent yellow, orange, or red are most common because they stand out in most weather and site conditions.

- Fluorescent Yellow-Green:

- Most common and effective in daylight and low-light conditions.

- Highly visible against most natural backgrounds (trees, soil, concrete).

- Used widely on construction sites, roadworks, and traffic control.

- Fluorescent Orange (Fluorescent Red-Orange):

- Better for urban areas or environments with a lot of green or yellow (like forests or grassy areas).

- Often used in roadwork zones or heavy machinery operations.

- Stands out well against blue skies and most building materials.

- Fluorescent Red:

- Less common but used in some specific cases where orange or yellow-green might blend in.

- Year-round necessity: Even in summer, bright sunlight can cause glare and visual “camouflage” against background materials; high-vis cuts through that.

Helmets (Hard Hats)

Purpose: Protect against falling objects, head bumps, and even electrical hazards if properly rated.

Standards: EN 397 (industrial safety helmets) and EN 50365 (electrical insulation).

Lifespan: Usually 3–5 years from manufacture, shorter if exposed to UV and chemicals.

Why always required: Many head injuries occur not from dramatic accidents but from low-clearance beams, swinging crane hooks, or dropped hand tools.

Read about helmets specifically from here: https://remato.com/blog/construction-hard-hat-color-meaning/

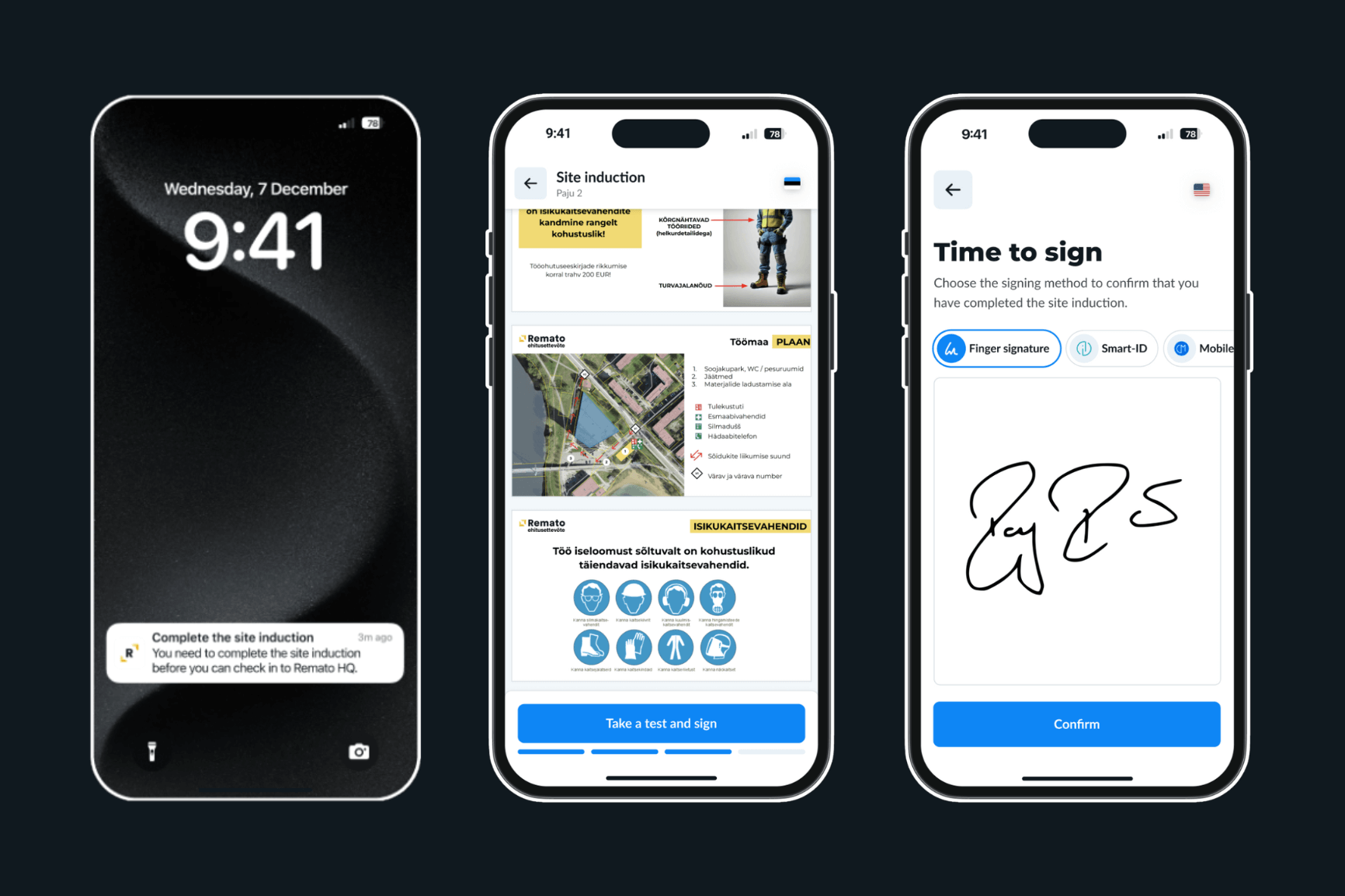

Digital Site Inductions for Consistent Construction Site Safety

Construction sites increasingly rely on digital solutions to maintain consistent safety standards. Platforms such as Remato Site Induction allow workers and visitors to complete site-specific safety briefings before entering the site. These inductions provide detailed guidance on hazards, PPE requirements, emergency procedures, and site rules. Consequently, every worker has access to the same information, and records are stored centrally for review or audits. In addition, digital induction reduces administrative delays and helps supervisors monitor compliance efficiently.

Risk Management and Safety Culture

1. Conduct site-specific risk assessments before work begins

Every construction site is unique. Risk assessments involve identifying all potential hazards, from physical dangers like scaffolding collapses and falling tools, to chemical exposure, noise, or electrical hazards. These assessments should be documented and updated whenever site conditions change, such as the arrival of new machinery, changes in weather, or the introduction of subcontractors. A well-conducted risk assessment informs all other safety measures on site.

2. Implement safe work systems, including scaffolding, fall prevention, and machinery guarding

Safe work systems are structured processes that make construction site safety tasks safer by design. For example:

- Scaffolding: Must meet EU standards (EN 12811) and be regularly inspected; guardrails, toe boards, and secure platforms reduce fall risk.

- Fall prevention: Use of harnesses, lifelines, and anchor points where guardrails are not feasible.

- Machinery guarding: Moving parts of cranes, grinders, or saws must have protective guards, emergency stop mechanisms, and clear operating procedures to prevent injury.

3. Schedule regular safety meetings to reinforce awareness

Toolbox talks or short site safety meetings keep safety top of mind. These meetings can highlight new risks, remind workers of proper procedures, discuss near-misses, and reinforce the correct use of PPE. Regular communication builds a proactive safety culture where everyone is alert and accountable.

4. Maintain clear signage and physical barriers around hazards

Signs should clearly indicate danger zones, mandatory PPE, and emergency procedures. Physical barriers such as guardrails, fences, and restricted zones prevent unauthorized access to high-risk areas, protecting both workers and visitors.

5. Report and investigate all incidents to prevent recurrence

Every accident, near-miss, or unsafe condition must be documented and investigated. Understanding the root cause helps implement corrective measures, updates work procedures, and prevents similar incidents. Documentation is also essential for regulatory compliance and audits.

6. Provide ongoing training and competency verification, especially for high-risk tasks

Workers must be trained not only when hired but continuously throughout the project. High-risk tasks like crane operation, welding, working at heights, or operating heavy machinery require certified training and periodic competence verification. Ongoing training ensures that safety procedures are understood and followed consistently.

7. Ensure emergency procedures, evacuation routes, and first aid are clearly defined and rehearsed

All sites must have clear, visible emergency procedures. Evacuation routes should be unobstructed and known to all personnel. Regular drills and first aid training ensure that workers can respond effectively in case of fire, injury, chemical spill, or other emergencies.

Benefits of Proper Construction Safety

1. Reduces accidents and injuries on site

Proactive safety measures, PPE, and training directly reduce the likelihood of falls, crush injuries, cuts, or chemical exposure, keeping workers healthy and productive.

2. Ensures compliance with EU directives and standards

Following Framework Directive 89/391/EEC and PPE Directive 89/656/EEC in construction site safety helps companies meet legal obligations, reducing the risk of penalties, fines, or work stoppages.

3. Promotes a culture of safety among all workers

When safety is integrated into everyday routines and reinforced through training, meetings, and clear procedures, it becomes part of the company culture. Workers are more likely to follow rules, report hazards, and support each other in safe practices.

4. Minimizes operational disruptions and liability risks

Fewer accidents mean less downtime, lower insurance claims, and a smoother project timeline. Proper documentation and safety measures protect the company from legal liabilities in case of incidents.

5. Protects both workers and the company’s reputation

A strong safety record demonstrates professionalism and reliability, which helps attract clients, skilled workers, and investors. It shows that the company values its workforce and takes responsibility seriously.

Conclusion

Construction site safety is a holistic system combining EU legislation, PPE, risk management, and a proactive safety culture. Adhering to directives 89/391/EEC and 89/656/EEC ensures hazards are managed effectively, PPE is used correctly, and workers are fully protected. Safety is is a fundamental responsibility of every construction company, safeguarding human life and operational success.