How to Prevent Rework and Material Waste with Construction Software

Construction projects are inherently time-sensitive and costly. Every day, a project falling behind schedule results in additional expenses, and even minor errors such as incorrect measurements or flawed decisions can lead to expensive rework. On top of this, millions of euros are lost annually in the construction industry due to materials being overordered, stored improperly, or left unused. Beyond the financial impact, wasted materials contribute to a larger environmental footprint, a growing concern for contractors and clients alike. In recent years, the construction industry has taken significant steps toward digitalization. Modern construction software is no longer limited to large-scale projects; it has become an accessible and user-friendly solution for smaller projects as well. From streamlined project management to real-time inventory tracking, these digital tools enable more intelligent decision-making, minimise errors, and maximise resource efficiency.

Importantly, construction software no longer functions in isolation. Today, it is possible to integrate quality control, BIM models, material ordering, and workforce planning into a single, unified system. This integration ensures that project managers, engineers, and on-site teams work from the same up-to-date information, allowing them to make rapid, data-driven decisions. In this article, we will explore how digital tools can significantly reduce rework and material waste and why investing in construction software benefits companies, employees, and the environment.

Table of Contents

1. Why Rework and Material Waste Are a Challenge

Rework occurs when completed work needs to be corrected or redone because it fails to meet project standards. This can include faulty structures, incorrect materials, or poorly planned tasks. Material waste often results from overordering or ineffective inventory management. Both issues lead to increased costs, delays, and operational stress, making them critical concerns for any construction project.

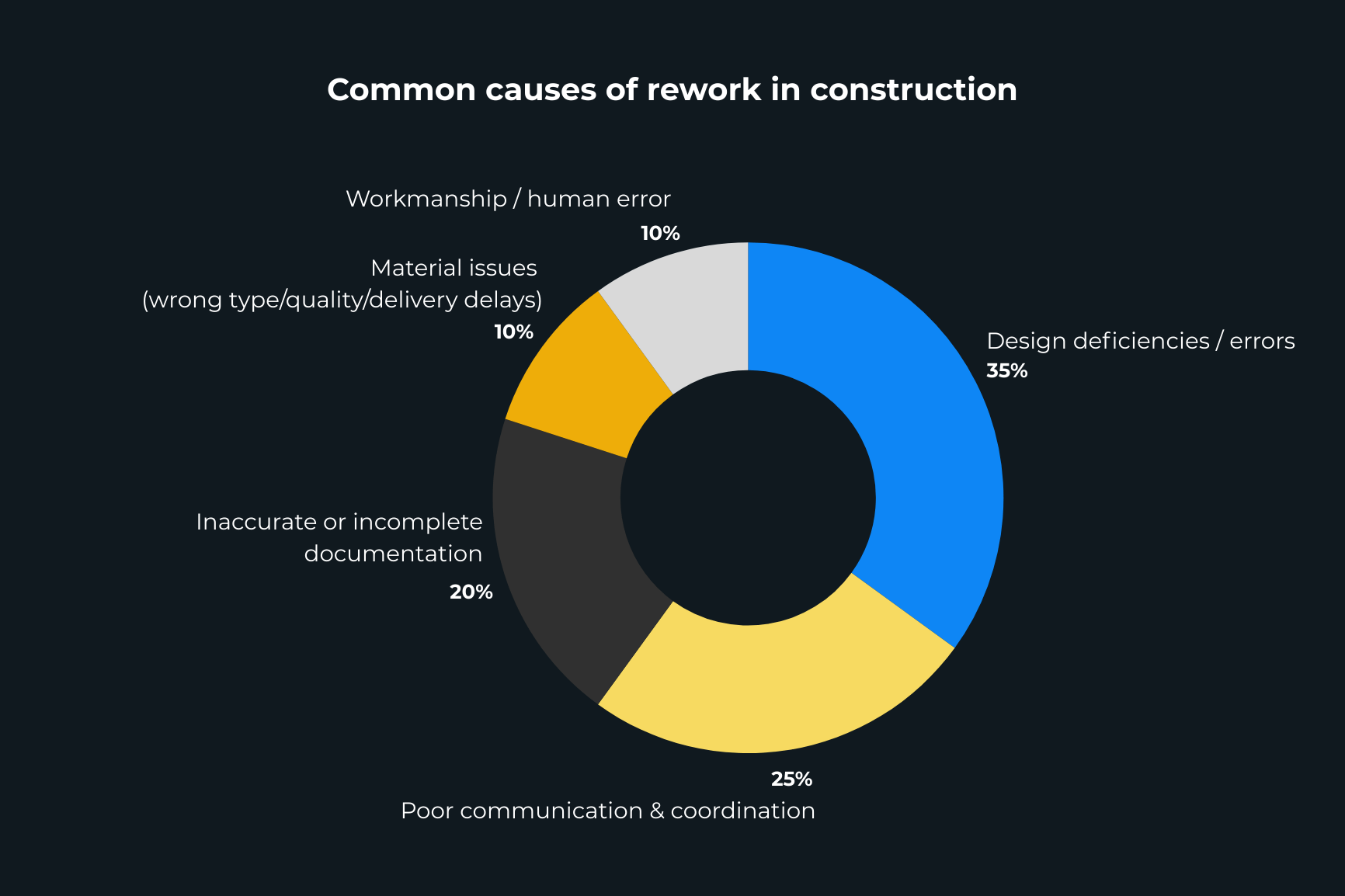

In fact, research shows that 14% of all rework is caused by bad data, while more than half stems from poor communication and project data issues [source]

2. Real-Time Material Tracking and Inventory Management

Modern construction software, such as Remato, enables real-time inventory tracking. This helps prevent over-ordering, reduces material waste, and ensures that resources are used efficiently. By maintaining an accurate overview of available materials, project teams can minimise excess stock and avoid unnecessary stress caused by shortages or mismanagement.

3. Real-Time Team Communication

Misunderstandings on construction sites are a leading cause of mistakes. Real-time messaging and notifications provided by construction software allow teams to resolve issues immediately. This prevents errors from escalating, avoids unnecessary rework, and keeps projects running smoothly.

4. Artificial Intelligence and Predictive Analytics

Artificial intelligence (AI) has become essential in optimising construction processes and minimising waste. AI-based solutions analyse historical project data, workload trends, and material usage patterns to forecast material requirements for upcoming tasks accurately. When combined with real-time tracking, AI can detect supply chain bottlenecks or anomalies early, warning before they escalate into costly problems. By relying on data-driven insights rather than assumptions, construction teams can make more precise decisions, reduce material waste, optimize schedules, and improve overall project profitability.

5. Accurate and Up-to-Date Documentation

Maintaining current and precise documentation is crucial for preventing mistakes. Working with outdated or inconsistent documents increases the risk of errors, leading to rework, incompatible materials, and costly delays. Cloud-based construction software ensures that all stakeholders—from project managers to on-site teams—have access to the exact, up-to-date drawings and documentation. It also tracks changes, recording who made updates and when, which promotes accountability and reduces misunderstandings. Regularly updated documentation prevents errors and improves collaboration between different teams. Decisions are based on accurate, real-time data rather than assumptions or incomplete notes. Clear and reliable documentation lays the foundation for smoother workflows, faster problem-solving, and more efficient project execution.

6. Clear Responsibility and Role Assignment

When not clearly defined who is responsible for a specific task, confusion can arise, often leading to rework. Construction software allows tasks and responsibilities to be assigned clearly, ensuring everyone knows their role. This clarity streamlines workflows, reduces errors, and makes project execution more efficient.

7. Regular Training and Software Practice

Even the most advanced and capable construction software will not deliver results if the team does not know how to use it effectively. Too often, companies invest in expensive systems, but employees only utilise a fraction of their capabilities. Regular training and continuous practice are therefore critical.

Training should go beyond the initial software introduction, including ongoing sessions that cover:

• how to use new features;

• troubleshooting common issues;

• practical tips to optimize workflow and efficiency.

Daily practice also builds confidence within the team. When workers or project managers see that the software makes their work easier and faster, it becomes a natural part of the process rather than a cumbersome task. A well-structured training program improves software proficiency and reduces errors and the risk of rework, as every step from data entry to reporting and photo documentation is executed correctly.

8. Data Collection and Analysis for Future Projects

Every construction project provides valuable insights for improving future work. By systematically collecting data—such as task completion times, material usage, and documented issues—teams can make more accurate forecasts and avoid repeating mistakes in subsequent projects. Photos play a key role in this process. Visual documentation helps to:

• record progress at each stage of the work;

• document mistakes and corrective actions;

• compare actual construction with project plans;

• analyse which methods and solutions proved most effective.

When these photos and data are accessible within a single cloud-based system, project managers and engineers can make better decisions for ongoing and future projects. Analysis may reveal, for example, that certain tasks consistently take longer than planned or that specific suppliers’ materials often lead to rework.

This data-driven approach enables construction companies to learn and refine their processes continually, reducing the risk of errors and waste on every new project.

9. The Most Frequently Redone Parts on Construction Sites

One of the construction projects’ most commonly redone aspects is MEP work – mechanical, electrical, and plumbing systems. This area’s work often arises from design deficiencies or poor coordination between different disciplines. For example, electrical and plumbing routes can conflict if drawings are not detailed or coordinated enough. Material waste in these cases includes pipes, wiring, fasteners, finishing materials, and insulation that must be redone or reinstalled. Addressing these issues early through proper planning and software-assisted coordination can significantly reduce rework and wasted materials.

10. Our Experience

In our team, it used to be standard that each project would encounter at least one major dispute – whether due to incomplete documentation, incorrect measurements, or delayed materials. This caused stress, wasted time, and constant tension between workers and managers. The situation changed completely after we started using unified construction software to manage projects. Everyone, from laborers to project managers had access to the same up-to-date information. Material movements were fully trackable, drawings were always current, and quality control processes were easy to document. The result? Workers now praise their managers, as there is less confusion, fewer disputes, and the work progresses at a calmer pace. Stress has decreased for both managers and workers, as everyone knows exactly what to do and when. This experience demonstrates that technology is not just a management tool it creates a better working environment for everyone, prevents conflicts, and smooths the construction process.

Summary

Construction software helps prevent rework and material waste in multiple ways:

| Solution | Benefit |

| Automated quality control | Reduced rework |

| Accurate inventory and material tracking | Less waste and overordering |

| AI forecasting and optimisation | More precise planning and logistics |

| Post-project reviews | Issues addressed proactively and in context |

| Pre-work planning and standards | More systematic and error-resistant processes |

| Continuous learning and process improvement | Ongoing efficiency and quality gains |